Izingxenye Zokunemba

-

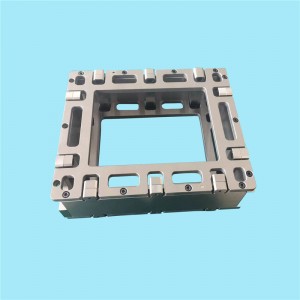

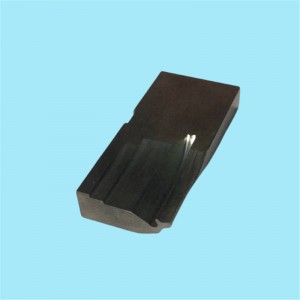

Izingxenye Zensimbi Engagqwali ezenziwe ngomshini we-CNC Precision

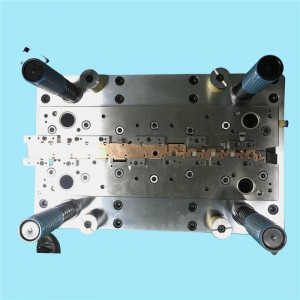

Iyini i-CNC precision machining futhi isebenza kanjani?

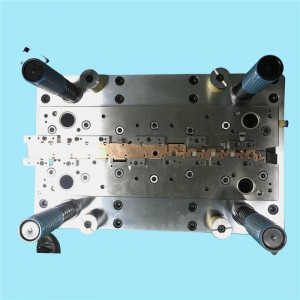

Inqubo yemishini ye-CNC isebenzisa ibhulokhi eliqinile lezinto ezifana nethusi, ithusi noma insimbi.Isebenzisa amathuluzi alawulwa ngezinombolo, iletha izingxenye ngendlela enembile futhi enembile ngezinga eliphezulu kakhulu.Izintambo, izigayo, amarutha, nezigayi kungamathuluzi ngokuvamile atholakala emishinini ye-CNC.Isifanekiso sedijithali kanye nemishini yokuzimela isusa iphutha lomuntu futhi izuze ukunemba phakathi kuka-1/1000.

Umshini we-CNC uhlelwe ngu-opharetha ngokusekelwe kumininingwane ebekwe emidwebeni ye-CAD.Inqubo yokuhlela ikhiqiza ikhodi elawula umshini ukuze ukhiqize umkhiqizo osuphelile ofunekayo.Ukuhlolwa kuqediwe ukuze kuqinisekiswe ukuthi awekho amaphutha ohlelweni.Lokhu kusebenza kokuhlola, okubizwa ngokuthi 'ukusika umoya' kuyingxenye yokwenziwa kwezingxenye eziqediwe zekhwalithi ephezulu futhi kuqeda kakhulu ukumoshwa kwezinto kanye nesikhathi sokuphumula esingadingekile.Lolu hlelo lungasetshenziswa ngokuphindaphindiwe ukudala imikhiqizo eminingi efanayo, yonke imiphumela ye-CNC ehambisana nokucaciswa okunembile kwesibonelo.

Ukusebenzisa umshini we-CNC nakho kuyashesha kakhulu kunomshini ojwayelekile, kuhlinzeka ngesevisi eyongayo eshintsha ngokushesha.

-

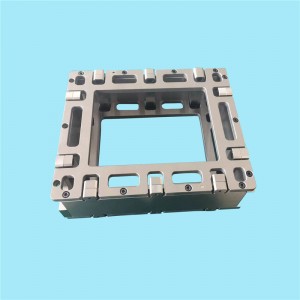

Izingxenye ze-CNC Custom Highly Precision Metal

Ziyini Izingxenye Zokunemba Okuphezulu?

Ingxenye enembayo ephezulu noma ukunemba kwemishini kungabonakala ngaso sonke isikhathi uma kuziwa ekuklameni, imishini yokukhiqiza, izingxenye, amathuluzi nokunye. Ngakho, ziyini ngempela, kungani sizidinga kuphrojekthi yokukhiqiza.

Izingxenye ezinemba okuphezulu noma ukunemba kwemishini kubhekise ezingxenyeni ezinokubekezelela ama-micrometer edijithi eyodwa.Umshini wakhiwe izingxenye eziningi ezinkulu nezincane, futhi uma zonke izingxenye zingenabo osayizi abathile, azikwazi ukuhlangana ziqine futhi zisebenze kahle.Ukuze umshini uhlangane ngokuqinile futhi usebenze ngendlela efanayo, abakhiqizi bemishini bazothola umhlinzeki wengxenye enemba ongabahlinzeka ngendawo ethile abayidingayo.

-

Izingxenye Zemishini Ye-CNC Ngokwezifiso Kakhulu

Ungadweba Kanjani Umdwebo Wengxenye Ye-Cnc Machined?

Hlaziya Izingxenye Futhi Unqume Izinkulumo

Ngaphambi kokudweba, kufanele uqale uqonde igama, umsebenzi wengxenye, indawo yayo emshinini noma engxenyeni, kanye nobuhlobo bokuxhumana bomhlangano.Ngaphansi kwesisekelo sokucacisa ukuma kwesakhiwo sengxenye, ngokuhambisana nendawo yayo yokusebenza kanye nesimo somshini, nquma ukuthi yiluphi uhlobo lwezingxenye ezine zezingxenye ezijwayelekile ezichazwe ngenhla (kokubili amabhushi, amadiski, izimfoloko namabhokisi), bese ngokusho kwe-Expression. izici zezingxenye ezifanayo, nquma isikimu senkulumo esifanele.

-

Izingxenye Zensimbi Ezenziwa Ku-inthanethi ze-CNC

I-OEM Parts Machining Services Iqinisekisa Izingxenye ze-OEM ezenziwe ngekhwalithi ephezulu

I-LongPan isiphenduke inkampani ethembekile yezingxenye ze-OEM ye-CNC yezinsizakalo zemishini eChina.Sinikezela ngobubanzi obuphelele bezinsizakalo zokumaka Izingxenye ze-OEM, ezisisiza ngezidingo ezahlukahlukene ezilula neziyinkimbinkimbi ngezikhathi zokushintsha ngokushesha.Singakwazi ukuphatha noma iyiphi iphrojekthi kusukela ekutholeni izinto zokusetshenziswa kuye ekudizayineni, ubunjiniyela, kanye nesakhiwo sesibonelo.Siyakwazisa ukulawulwa kwekhwalithi, nokuthobela imithetho, okusisiza ukuthi siqinisekise ikhwalithi kuyo yonke imikhiqizo yethu.Sinolwazi olukhulu ekwakheni izingxenye zamakhasimende kwezokuvikela, i-semiconductor, izimboni ze-aerospace nokunye.

-

Inqubo Yezingxenye Zokunemba ze-CNC

Izicelo ze-CNC Machining:

I-CNC machining iyinqubo yokukhiqiza eguquguqukayo futhi engabizi.Le nqubo iyahambisana nohlu olukhulu lwezinto zokwakha.Kanjalo, ukwenziwa kwemishini ye-CNC kusiza ezimbonini eziningi ezahlukahlukene zezinhlelo zokusebenza ezahlukahlukene.Abakhiqizi nabakhi bemishini basebenzisa le nqubo ngezindlela ezihlukahlukene.Lokhu kubandakanya inqubo yokukhiqiza eqondile, inqubo yokukhiqiza engaqondile, noma ngokuhlangana nezinye izinqubo.

Njenganoma iyiphi inqubo yokukhiqiza, izinzuzo eziyingqayizivele zemishini ye-CNC zazisa uhlobo lwezinhlelo ezingasetshenziswa kuzo.Nokho, izinzuzo ze-CNC zifiseleka cishe kunoma iyiphi imboni.Zifanele izingxenye eziningi nemikhiqizo.Njengoba imishini ye-CNC ingacubungula cishe noma yiluphi uhlobo lwempahla, izicelo zabo ziseduze nokungenamkhawulo.

Ukusuka ekukhiqizweni kwengxenye eqondile ukuya ekufanekiseni okusheshayo, lesi sihloko sibheka izinhlelo zokusebenza eziqinile zemishini ye-CNC.Ake siqonde kuyo!

-

Izingxenye Zokubumba ezenziwe ngomshini ze-CNC ezinembile

Izimboni Ezisebenzisa CNC Machining

I-Consumer Electronics

Imishini ye-CNC iphinde isize ekwenzeni i-prototyping kanye nokukhiqizwa kwama-electronics abathengi.Lawa ma-electronics afaka amalaptop, ama-smartphones, nokunye okuningi.I-chassis ye-Apple MacBook, isibonelo, ivela kumshini we-CNC we-aluminium extruded bese i-anodized.

Embonini ye-elekthronikhi, umshini we-CNC usiza ukudala ama-PCB, izindlu, amajigi, izinto ezilungiswayo, nezinye izinto.

-

Izingxenye Zokubumba Umjovo Onembile Kakhulu

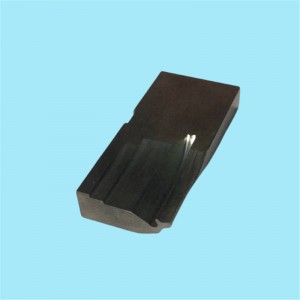

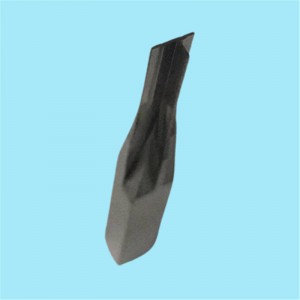

Izidingo zokusebenza kwezingxenye zesikhunta ezinembayo

1. Amandla nokuqina

Isikhunta esinembe kakhulu nezingxenye zamathuluzi ngokuvamile zisebenza ngaphansi kwesimo esinzima.Ezinye zivame ukuthwala umthwalo omkhulu womthelela, okuholela ekuqhekekeni okuphukile.Ngakho-ke, isikhunta esinembayo kufanele sibe namandla aphezulu kanye nokuqina.Okokuvikela izingxenye zesikhunta ukuthi zingaphuki kungazelelwe ngesikhathi sokusebenza.Futhi ukuqina kwesikhunta nethuluzi ikakhulukazi kuncike kokuqukethwe kwekhabhoni, usayizi wokusanhlamvu, kanye ne-microstructure yezinto.

2. Ukusebenza kokuphuka kokukhathala

Ukuphuka kokukhathala kwenzeka njalo lapho izingxenye zesikhunta zepulasitiki ezinembayo eziphezulu zisebenza.Kungenxa yemiphumela yesikhathi eside ye-cyclic stress.Amafomu afaka umthelela omningi ngamandla amancane, ukunwebeka, ukuthintana, nokugoba ukukhathala.Ngokuvamile, le mpahla yokubunjwa ngokwezifiso kanye ne-tooling incike kulezi zici.Njengamandla ayo, ukuqina, ubulukhuni, nokuqukethwe okufakiwe kokubalulekile.

-

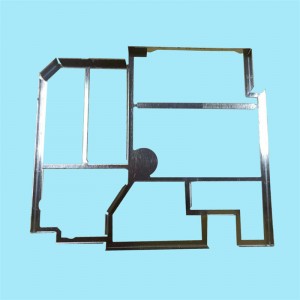

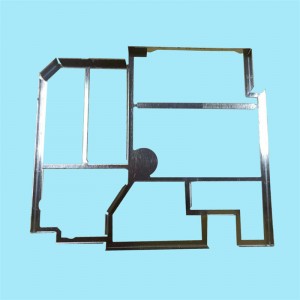

I-Precision Sheet Izingxenye Zensimbi Nezitembu

Izinhlobo Ze-Sheet Metal Stamping Processes

Kunezinqubo eziningi zokugxiviza zensimbi ezihlukene.Ngayinye yazo iyisisekelo impela kepha njengenhlanganisela, ingakwazi ukukhiqiza cishe noma iyiphi i-geometry engenzeka.Nazi izinqubo zokugxiviza zensimbi zeshidi ezisakazeke kakhulu.

Ukungasho lutho kuvamise ukuba wukuhlinzwa kokuqala okumele kwenziwe phakathi kwezinqubo zokugxiviza.Idinga umshini wokugxiviza ngesibhakela esibukhali.Amashidi ensimbi avame ukunikezwa ngamasayizi amakhulu njenge-3 × 1,5 m.Izingxenye eziningi azinkulu kangako, ngakho-ke uzodinga ukusika ingxenye yeshidi engxenyeni yakho, futhi kungaba kuhle ukuthola ikhonsathi oyifunayo yengxenye yokugcina khona lapha.Ngakho-ke, ukuvala kusetshenziswa ukuze uthole i-contour oyidingayo.Qaphela ukuthi kunezinye izindlela zokwenza ishidi lensimbi lingenalutho njengokusika kwe-laser, ukusika i-plasma noma ukusika indiza yamanzi.

-

CNC Machining Materials for Stainless Steel Izingxenye

Insimbi engagqwali imelana kakhulu nokugqwala nokugqwala, okuyenza ifanelekele ukusetshenziswa lapho izingxenye zingase zembulwe ezingxenyeni isikhathi eside.Insimbi engagqwali ngaphezu kwalokho i-ductile kanye ne-ductile.I-JTR inikezela ngezinhlobonhlobo zama-alloys ensimbi engagqwali, ahlanganisa amabanga aphephile ekudleni.

Uchungechunge lwama-300 (303, 304, njalo njalo) luyizinsimbi ezingenasici ze-austenitic (ngokusekelwe ohlakeni lwazo lwekristalu) futhi zingamamaki akhiqizwa kakhulu emhlabeni jikelele.Amabanga ensimbi engagqwali ye-Austenitic aziwa ngokumelana nokuwohloka okuphezulu kanye nokuqina okuphezulu ezinhlobonhlobo ezinkulu zokushisa.Ngaphandle kokusebenza okupholile, awelapheki ngokushisa futhi awawona ama-magnetic.