Lo mhlahlandlela obanzi uqhathanisa izinto ezingama-25 ezisetshenziswa kakhulu emishinini ye-CNC futhi usiza ukuthi ukhethe okulungile kuhlelo lwakho lokusebenza.

Imishini ye-CNC ingakhiqiza izingxenye cishe kunoma iyiphi insimbi noma ipulasitiki.Uma kunjalo, kunohlu olukhulu lwezinto ezitholakalayo zezingxenye ezikhiqizwe nge-CNC milling nokujika.Ukukhetha okulungile kuhlelo lwakho lokusebenza kungaba inselele impela, futhi ukuqonda izinzuzo nokusetshenziswa okungcono kakhulu kwento ngayinye etholakalayo kungabaluleka.

Kulesi sihloko, siqhathanisa izinto ezivame kakhulu ze-CNC, ngokwezakhiwo zemishini nezokushisa, izindleko kanye nezinhlelo zokusebenza ezijwayelekile (futhi ezifanele).

Uzikhetha kanjani izinto zokwakha ze-CNC ezifanele?

Lapho uklama ingxenye ezokwenziwa ngomshini we-CNC, ukukhetha izinto ezifanele kubalulekile.Nazi izinyathelo eziyisisekelo esitusa ukuzilandela ukuze ukhethe izinto ezifanele zezingxenye zakho zangokwezifiso.

Chaza izidingo zezinto ezibonakalayo: Lezi zingabandakanya izidingo zemishini, ezishisayo noma ezinye izinto, kanye nezindleko nokuqedwa kwendawo.Cabangela indlela ozozisebenzisa ngayo izingxenye zakho nokuthi hlobo luni lwendawo ezizoba kuyo.

Khomba izinto ezisetshenziswayo: Phina izinto ezimbalwa zekhandidethi ezigcwalisa zonke (noma eziningi) zezidingo zakho zokuklama.

Khetha into efanelekile kakhulu: Ukuvumelana ngokuvamile kuyadingeka lapha phakathi kwezimfuneko ezimbili noma ngaphezulu zedizayini (isibonelo, ukusebenza kwemishini kanye nezindleko).

Kulesi sihloko, sizogxila esinyathelweni sesibili.Usebenzisa ulwazi olwethulwe ngezansi, ungakwazi ukuhlonza izinto ezilungele isicelo sakho, kuyilapho ugcina iphrojekthi yakho kubhajethi.

Yiziphi iziqondiso zeHubs zokukhetha izinto zokwakha ze-CNC?

Kumathebula angezansi, sifingqa izici ezifanele zezinto ezivame kakhulu ze-CNC, eziqoqwe ngokuhlola imininingwane yedatha enikezwe abakhiqizi bezinto ezibonakalayo.Sihlukanisa izinsimbi namapulasitiki abe izigaba ezimbili ezihlukene.

Izinsimbi zisetshenziswa kakhulu ekusetshenzisweni okudinga amandla aphezulu, ubulukhuni kanye nokumelana nokushisa.Amapulastiki ayizinto ezingasindi ezinezinhlobonhlobo zezakhiwo ezibonakalayo, ezivame ukusetshenziselwa ukumelana namakhemikhali kanye nekhono lokuhlukanisa ugesi.

Ekuqhathaniseni kwethu izinto ze-CNC, sigxila emandleni emishini (avezwa njengamandla esivuno esiqinile), ukusebenziseka (ukuba lula komshini kuthinta amanani entengo ye-CNC), izindleko, ubulukhuni (ikakhulukazi okwezinsimbi) kanye nokumelana nezinga lokushisa (ikakhulukazi kumapulasitiki).

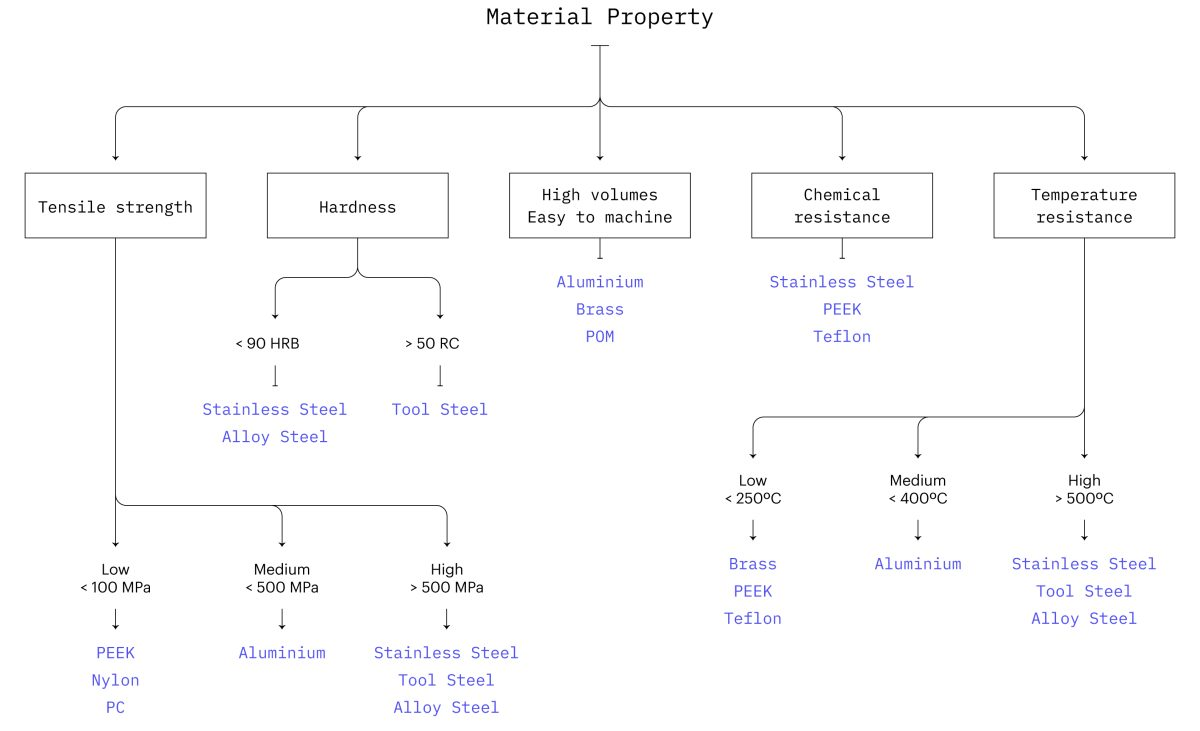

Nansi i-infographic ongayisebenzisa njengereferensi esheshayo yokuhlonza ngokushesha izinto ze-CNC ezilingana nezidingo ezithile zobunjiniyela:

Iyini i-aluminium?I-alloy eqinile, eyongayo

Ingxenye eyenziwe nge-Aluminium 6061

Ama-alloys e-aluminium anesilinganiso esihle kakhulu samandla nesisindo, ukuguquguquka okuphezulu kwe-thermal kanye nogesi kanye nokuvikelwa kwemvelo ngokumelene nokugqwala.Alula ukuwenza ngomshini futhi angabizi ngobuningi, ngokuvamile okuwenza abe inketho yokonga kakhulu yokukhiqiza ama-prototypes nezinye izinhlobo zezingxenye.

Nakuba ama-alloys e-aluminium ngokuvamile enamandla aphansi nobulukhuni kunezinsimbi, kodwa angenziwa i-anodized, enze isendlalelo esiqinile, esivikelayo endaweni yawo.

Ake sihlukanise izinhlobo ezahlukene zama-alloys e-aluminium.

❖ I-Aluminium 6061 iyingxubevange evame ukusetshenziswa kakhulu, esetshenziswa ngokujwayelekile, enesilinganiso esihle samandla nesisindo kanye nokusebenza kahle kakhulu.

❖ I-Aluminiyamu 6082 inokwakheka okufanayo nezinto ezibonakalayo ku-6061. Isetshenziswa kakhulu e-Europe (njengoba ithobelana Namazinga WaseBrithani).

❖ I-Aluminiyamu 7075 iyingxubevange esetshenziswa kakhulu ezindaweni zokusebenza zasemkhathini lapho ukuncipha kwesisindo kubaluleke kakhulu.Inezici ezinhle kakhulu zokukhathala futhi ingaphathwa ukushisa ibe namandla aphezulu kanye nokuba lukhuni, okuyenza ifaniswe nezinsimbi.

❖ I-Aluminium 5083 inamandla amakhulu kunamanye ama-alloy amaningi kanye nokumelana okukhethekile namanzi olwandle.Lokhu kuyenza ilungele ukwakhiwa kanye nezicelo zasolwandle.Futhi kuyisinqumo esihle kakhulu sokushisela.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile kwama-alloys e-aluminium: 2.65-2.80 g/cm3

❖ Ingagcotshwa

❖ Akunazibuthe

Iyini insimbi engagqwali?Ingxubevange eqinile, ehlala isikhathi eside

Ingxenye eyenziwe nge-Stainless Steel 304

Ama-alloys ensimbi engagqwali anamandla aphezulu, i-ductility ephezulu, ukuguga okuhle kakhulu nokumelana nokugqwala futhi angashiselwa kalula, enziwe ngomshini futhi apholishwe.Ngokuya ngokwakheka kwazo, zingaba (empeleni) ezingezona kazibuthe noma zikazibuthe.

Ake sihlukanise izinhlobo zensimbi engagqwali esizinikeza endaweni yesikhulumi.

❖ Insimbi engagqwali 304 iyingxubevange evamile yensimbi engagqwali.Inezici ezinhle kakhulu zemishini kanye nokusebenza kahle komshini.Iyakwazi ukumelana nezimo eziningi zemvelo kanye nemithombo yezindaba eyonakalisayo.

❖ Insimbi engagqwali 316 enye ingxubevange evamile yensimbi engagqwali enezici zomshini ezifanayo nezika-304. Inokugqwala okuphakeme kanye nokumelana namakhemikhali nakuba, ikakhulukazi emanzini anosawoti (ngokwesibonelo amanzi olwandle), ngakho-ke kuvame ukuba ngcono ukubhekana nezindawo eziqinile.

❖ Insimbi engagqwali engu-2205 iDuplex inamandla amakhulu kakhulu (aphindwe kabili kunama-alloys ensimbi evamile) kanye nokumelana kahle nokugqwala.Isetshenziswa ezindaweni ezeqisayo, kanye nezinhlelo eziningi ku-Oyili negesi.

❖ Insimbi engagqwali 303 inokuqina okuhle kakhulu, kodwa ukumelana nokugqwala okuphansi uma kuqhathaniswa no-304. Ngenxa yobuciko bayo obuhle kakhulu, ivamise ukusetshenziswa ezindaweni ezinevolumu ephezulu, njengokukhiqiza amantongomane namabhawodi endaweni yendiza.

❖ Insimbi engagqwali 17-4 (i-SAE grade 630) inezinto eziwumshini eziqhathaniswa no-304. Ikwazi ukuna iqine ibe sezingeni eliphezulu kakhulu (iqhathaniseka nezinsimbi zamathuluzi) futhi inokumelana namakhemikhali okuhle kakhulu, okuyenza ifanelekele izinhlelo zokusebenza ezisebenza kahle kakhulu, njengama-blade okukhiqiza ama-wind turbines.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 7.7-8.0 g/cm3

❖ Ama-alloys ensimbi engenazibuthe: 304, 316, 303

❖ Izingxube zensimbi engagqwali kazibuthe: 2205 Duplex, 17-4

Iyini insimbi emnene?I-alloy yenhloso evamile

Ingxenye eyenziwe nge-Mild Steel 1018

Izinsimbi ezithambilezaziwa nangokuthi izinsimbi ezinekhabhoni ephansi futhi zinezakhiwo ezinhle zemishini, ukusebenza kahle okukhulu kanye nokushisela okuhle.Ngenxa yokuthi zibiza kancane, abakhiqizi bawasebenzisela izinhlelo eziningi ezijwayelekile, njengama-jigs kanye nezakhiwo.Izinsimbi ezithambile zisengozini yokugqwala kanye nokulimala kwamakhemikhali.

Ake sihlukanise izinhlobo zezinsimbi ezithambile ezitholakala endaweni yesikhulumi.

❖ Insimbi eyi-Mild 1018 iyingxubevange yokusetshenziswa okujwayelekile ekwazi ukwenza izinto kahle nokushisela kanye nokuqina okuhle kakhulu, amandla nobulukhuni.Yinsimbi esetshenziswa kakhulu emnene.

❖ Insimbi eyi-Mild 1045 iyinsimbi ye-carbon steel ekwazi ukushisela, ikwazi ukusebenza kahle namandla amakhulu kanye nokumelana nomthelela.

❖ Insimbi i-Mild A36 iyinsimbi evamile yesakhiwo eshisela kahle.Ilungele izinhlelo zokusebenza ezihlukene zezimboni nezokwakha.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 7.8-7.9 g/cm3

❖ Uzibuthe

Iyini insimbi ye-alloy?Ingxubevange eqinile, engagugi

Ingxenye eyenziwe ngensimbi ye-alloy

Izinsimbi ze-alloy ziqukethe ezinye izakhi ze-alloying ngaphezu kwekhabhoni, okuholela ekuqineni okuthuthukisiwe, ukuqina, ukukhathala nokumelana nokuguga.Ngokufanayo nezinsimbi ezithambile, izinsimbi ze-alloy zisengozini yokugqwala nokuhlaselwa ngamakhemikhali.

❖ Insimbi ye-alloy 4140 inezakhiwo ezinhle zokusebenza kwayo yonke, inamandla amahle kanye nokuqina.Le alloy ifanele izicelo eziningi zezimboni kodwa ayinconywa ukushisela.

❖ Insimbi eyingxubevange engu-4340 ingaphathwa ukushisa ibe namandla aphezulu kanye nobulukhuni, kuyilapho igcina ukuqina kwayo okuhle, ukumelana nokugqoka kanye namandla okukhathala.Le alloy iyashisela.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 7.8-7.9 g/cm3

❖ Uzibuthe

Iyini insimbi yensimbi?Ingxubevange eqinile futhi imelana

Ingxenye eyenziwe ngensimbi yamathuluzi

Izinsimbi zamathuluziama-alloys ensimbi anobunzima obuphakeme kakhulu, ukuqina, ukuhuzuka nokumelana nokushisa, inqobo nje uma edlula.ukwelashwa ukushisa.Asetshenziselwa ukwakha amathuluzi okukhiqiza (yingakho igama) elifana namafa, izitembu nezibunji.

Masihlukanise izinsimbi zamathuluzi esiwanikezayo kuma-Hubs.

❖ Insimbi yensimbi i-D2 iyingxubevange engagugi egcina ubulukhuni bayo bufinyelele ku-425°C.Ivame ukusetshenziselwa ukwenza amathuluzi okusika futhi iyafa.

❖ Insimbi yensimbi engu-A2 iyinsimbi yenjongo evamile eqinile emoyeni enokuqina okuhle kanye nokuzinza okuhle kakhulu kwe-dimensional emazingeni okushisa aphakeme.Kuvame ukusetshenziselwa ukwenza umjovo wokubumba uyafa.

❖ Insimbi yensimbi i-O1 iyingxubevange eqiniswe ngamafutha enokuqina okuphezulu okungu-65 HRC.Ivamise ukusetshenziselwa imimese namathuluzi okusika.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 7.8 g/cm3

❖ Ubulukhuni obujwayelekile: 45-65 HRC

Liyini ithusi?Ingxubevange ye-conductive & cosmetic

Ingxenye ye-Brass C36000

Ithusiiyingxubevange yensimbi ekwazi ukusebenza kahle kanye nokuhamba kahle kukagesi, okwenza kube kuhle ezinhlelweni ezidinga ukungqubuzana okuphansi.Ngokuvamile uzothola izingxenye zethusi zezimonyo ezisetshenziselwa izinhloso zezakhiwo (imininingwane yegolide).

Nali ithusi esilinikezayo kuma-Hubs.

❖ I-Brass C36000 iyimpahla enamandla aqine kakhulu futhi imelana nokugqwala kwemvelo.Ingenye yezinto ezisebenziseka kalula, ngakho-ke ivame ukusetshenziselwa izinhlelo zokusebenza zevolumu ephezulu.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 8.4-8.7 g/cm3

❖ Akunazibuthe

Iyini i-ABS?I-prototyping thermoplastic

Ingxenye eyenziwe nge-ABS

I-ABSingenye yezinto ezivame kakhulu ze-thermoplastic ezinikeza izakhiwo ezinhle zokukhanda, amandla omthelela amahle kakhulu, ukumelana nokushisa okuphezulu kanye nokusebenza kahle komshini.

I-ABS inokuminyana okuphansi, okuyenza ilungele izinhlelo zokusebenza ezingasindi.Izingxenye ze-ABS zomshini we-CNC zivame ukusetshenziswa njengezibonelo ngaphambi kokukhiqizwa ngobuningi ngokubumba komjovo.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 1.00-1.05 g/cm3

Yini inayiloni?Ubunjiniyela be-thermoplastic

Ingxenye eyenziwe inayiloni

Inayiloni(i-aka polyamide (PA)) iyi-thermoplastic evame ukusetshenziselwa izicelo zobunjiniyela, ngenxa yezakhiwo zayo ezinhle kakhulu zemishini, amandla omthelela amahle kanye nokumelana okuphezulu kwamakhemikhali nokuhuzuka.Ingenwa kalula amanzi kanye nomswakama.

Inayiloni 6 kanye nenayiloni 66 amamaki asetshenziswa kakhulu emishinini ye-CNC.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 1.14 g/cm3

Iyini i-polycarbonate?I-thermoplastic enamandla okuthinta

Ingxenye eyenziwe nge-polycarbonate

I-Polycarbonate iyi-thermoplastic enokuqina okuphezulu, ukusebenziseka okuhle namandla omthelela amahle kakhulu (ingcono kune-ABS).Ivamise ukuba sobala, kodwa ingadaywa ngemibala ehlukahlukene.Lezi zici ziyenza ifaneleke kuhlelo olubanzi lwezinhlelo zokusebenza, okuhlanganisa amadivaysi e-fluidic noma i-auto glazing.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 1.20-1.22 g/cm3

Iyini i-POM (Delrin)?Ipulasitiki ye-CNC esebenza kakhulu

Ingxenye eyenziwe ngePOM (Delrin)

I-POM yaziwa kakhulu ngegama lezentengiselwano i-Delrin, futhi iyi-thermoplastic yobunjiniyela enamandla kakhulu phakathi kwamapulasitiki.

I-POM (i-Delrin) ngokuvamile iyisinqumo esingcono kakhulu lapho i-CNC ikhiqiza izingxenye zepulasitiki ezidinga ukunemba okuphezulu, ukuqina okuphezulu, ukungqubuzana okuphansi, ukuzinza okuhle kakhulu kwe-dimensional emazingeni okushisa aphakeme kanye nokumuncwa kwamanzi aphansi kakhulu.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 1.40-1.42 g/cm3

Iyini i-PTFE (Teflon)?Izinga lokushisa eliphakeme kakhulu le-thermoplastic

Ingxenye eyenziwe nge-PTFE

I-PTFE, evame ukubizwa ngokuthi i-Teflon, iyi-thermoplastic yobunjiniyela enamakhemikhali nokumelana nokushisa okuhle kakhulu kanye ne-coefficient ephansi yokungqubuzana kwanoma yikuphi okuqinile okwaziwayo.Ingenye yamapulasitiki ambalwa akwazi ukumelana namazinga okushisa okusebenza angaphezu kuka-200 degrees Celsius futhi iyisivikeli esivelele sikagesi.Ibuye ibe nezinto ezihlanzekile zemishini futhi ivame ukusetshenziswa njengolwelwesi noma ukufakwa emhlanganweni.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 2.2 g/cm3

Iyini i-HDPE?I-thermoplastic yangaphandle nepayipi

Ingxenye eyenziwe nge-HDPE

I-polyethylene ephezulu kakhulu (i-HDPE)iyi-thermoplastic enesilinganiso esiphezulu samandla nesisindo, amandla omthelela aphezulu kanye nokumelana nesimo sezulu esihle.I-HDPE ayisindi futhi ilungele ukusetshenziswa ngaphandle namapayipi.Njenge-ABS, ivame ukusetshenziselwa ukudala ama-prototypes ngaphambi kokubunjwa komjovo.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 0.93-0.97 g/cm3

Yini i-PEEK?Ipulasitiki esikhundleni sensimbi

Ingxenye ekhiqizwe kwa-PEEK

I-PEEKiyi-thermoplastic yobunjiniyela esebenza kahle kakhulu enezici ezinhle kakhulu zemishini, ukuzinza kokushisa phezu kwebanga elibanzi kakhulu lamazinga okushisa kanye nokumelana okuhle kakhulu namakhemikhali amaningi.

I-PEEK ivame ukusetshenziselwa ukushintsha izingxenye zensimbi ngenxa yesilinganiso sayo esiphezulu samandla kuya kwesisindo.Amamaki ezokwelapha nawo ayatholakala, okwenza i-PEEK ifanele futhi izicelo ze-biomedical.

Izici zezinto ezibonakalayo:

❖ Ukuminyana okujwayelekile: 1.32 g/cm3

Imibuzo ejwayelekile ukubuzwa

❖ Yiziphi izinzuzo zomshini we-CNC ngezinsimbi?

Izinsimbi zilungele ukukhiqiza izicelo ezidinga amandla aphezulu, ubulukhuni kanye/noma ukumelana okuthembekile emazingeni okushisa aphezulu.

Umthombo we-athikili:https://www.hubs.com/knowledge-hub/?topic=CNC+machining

Isikhathi sokuthumela: May-10-2023