Ukusika intambo

Ngokuvamile kubhekiselwa endleleni yokucubungula izintambo kucezu lokusebenza ngamathuluzi okwakha noma ama-abrasives, ikakhulukazi ukuphenduka, ukugaya, ukuthepha, ukuthunga, ukugaya, ukusika nokusika isishingishane.Lapho ujika, ukugaya nokugaya izintambo, iketango lokushayela lethuluzi lomshini liqinisekisa ukuthi ithuluzi eliphendukayo, ithuluzi lokugaya noma isondo lokugaya lihamba ngokunembile nangokulinganayo eduze kokuqondisa kwe-axial yesiqeshana sokusebenza sokuphenduka ngakunye kwendawo yokusebenza.Ekuthepheni noma ekucupheni, ithuluzi (umpompi noma ipuleti) lihamba ngokuzungezisayo liye kucezu lokusebenza futhi liqondiswa i-thread groove eyakhiwe kuqala ukuze ihambise ithuluzi (noma ucezu lokusebenza) nge-axially.

Ukuphendulela izintambo ku-lathe kungenziwa ngethuluzi lokubumba noma ngekama lentambo (bona Amathuluzi Okulutha).Ukuguqula intambo ngethuluzi lokwakha kuyindlela evamile yokukhiqizwa kwesiqephu esisodwa kanye neqoqo elincane lama-workpieces anentambo ngenxa yesakhiwo sayo esilula samathuluzi;ukuphenduka kwentambo ngethuluzi lokuhlanganisa intambo kukhiqiza kakhulu, kodwa isakhiwo samathuluzi siyinkimbinkimbi futhi sifaneleka kuphela ukuguqula ama-workpieces anemicu emifushane enamazinyo amahle ekukhiqizeni inqwaba ephakathi nendawo enkulu.Ukunemba kwe-pitch yezintambo ezijwayelekile ze-lathe eziphendukayo ze-trapezoidal zingafinyelela kuphela ibanga le-8 ~ 9 (JB 2886-81, efanayo ngezansi);ukukhiqiza noma ukunemba kungathuthukiswa kakhulu ngokucubungula izintambo emshinini okhethekile wokuguqula intambo.

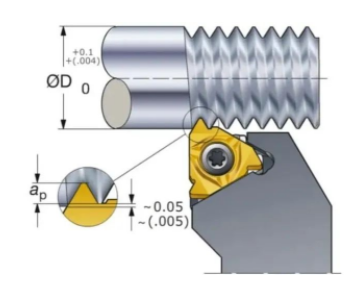

I-Thread Milling

Ukugaywa emshinini wokugaya intambo nge-disc noma i-comb milling cutter.Abasiki be-disc milling basetshenziswa kakhulu ekugayeni imicu yangaphandle ye-trapezoidal ezintweni zokusebenza ezifana nezikulufu kanye nama-worm shafts.Ama-comb milling cutters asetshenziselwa ukugaya imicu evamile yangaphakathi neyangaphandle kanye nemicu ecijile.Njengoba i-workpiece igaywe nge-multi-edged cutter futhi ubude bengxenye yokusebenza bukhulu kunobude bentambo okufanele yenziwe ngomshini, i-workpiece ingenziwa ngomshini ngokuguqulwa kwe-1.25 kuya ku-1.5 kuphela, okuholela ekukhiqizeni okuphezulu.Ukunemba kwephimbo lokugaywa kwentambo ngokuvamile kuba yibanga lesi-8~9.Le ndlela ifaneleka ekukhiqizeni iqoqo lomsebenzi wentambo wokunemba okuvamile noma ukugaywa okuqinile ngaphambi kokugaya.

Ukugaya intambo

Isetshenziselwa ikakhulukazi ukwenza imicu enembile yezingcezu zokusebenza eziqinile emishinini yokugaya intambo.

Ukugaya intambo kuhlukaniswe isondo elilodwa lokugaya intambo kanye nesondo lokugaya izintambo eziningi ngokuya ngokuma kwesigaba sesiphambano sesondo lokugaya.Ukugaya intambo eyodwa kungafinyelela ukunemba kwe-pitch okungu-5~6, ukuhwaqeka kwangaphezulu kwe-Ra1.25~0.08 micron, kanye nokugqoka amasondo okulula.

Le ndlela ilungele ukugaya izikulufu ezinembayo, amageji entambo, amagiya wezikelemu, izinto zokusebenza ezinentambo emincane kanye nezinsimbi zokunemba zokugaya amafosholo.Ukugaya nge-Multiline kuhlukaniswe ngezinhlobo ezimbili: ukugaya i-longitudinal kanye nokugaya.Endleleni yokugaya i-longitudinal, ububanzi besondo lokugaya buncane kunobude bentambo okufanele igaywe, futhi isondo lokugaya linganyakaziswa ngobude ngomvimbo owodwa noma eminingana ukuze ligaye intambo ifinyelele ubukhulu bayo bokugcina.Endleleni yokugaya i-plunge, ububanzi besondo lokugaya bukhulu kunobude bentambo okufanele igaywe, futhi isondo lokugaya lisikwa phezulu endaweni yokusebenza, futhi ucezu lokusebenza lungagaywa cishe ngama-revolution angu-1.25, ngakho-ke. ukukhiqiza kuphakeme, kodwa ukunemba kuphansi kancane futhi ukugqoka kwesondo lokugaya kuyinkimbinkimbi.Indlela yokugaya i-plunge ilungele ukufofa ompompi abaningi kanye nokugaya imicu ethile ukuze kuhlanganiswe.

Isikhathi sokuthumela: Sep-15-2022